Risk Assesment

When we run a tap in the kitchen to clean our dishes, drink a glass of water, or turn on the shower in the bathroom to get clean, we never truly think about the process that goes into making our water so healthy. Behind the scenes, there is a whole system and process that takes place in order for it to be consumed by us in the UK.

The earth’s hydrological cycle is the process in which water moves from the land and ocean’s surface up into the atmosphere and back down again in the form of precipitation.

The constant cycle means that filtration is infinitely happening through evaporation, condensation and surface runoff. In order for this water to be fit for consumption we need to recreate this process and add in a number of factors before entering the domestic system.

Across the world, it’s clear to see how first-world countries are fortunate to have a clean and safe water supply, in comparison to developing countries which face poorer water quality. Throughout history, the ability to maintain water treatment for a growing population has been challenging, but due to technological developments, much has improved. By monitoring and assessing water states we’re able to cleanse water through a number of natural processes to make it as pure as possible.

This varies depending on the type of water and the quality entering the water plant – for example, groundwater vs surface water and the number of steps that are required to purify it. In some cases, a water supply may contain inorganic and organic chemicals as well as disinfection by-products which require specialist treatment.

There are a number of factors that may be lying beneath the surface of water that needs cleansing, such as algae, turbidity, the need to remove colour and other microorganisms. This is achieved with coagulation, sedimentation and flocculation, as well as the addition of chemical coagulants for the formation of a precipitate to trap and then remove these impurities. This is an effective way to remove fine particles at the end of the mixing and monitoring journey.

The process is certainly one that’s in-depth and follows six particular steps in order to achieve success in water purification ahead of it being distributed to the masses.

For surface water, screens are used to remove weeds, fish, debris and particulate material from raw water. This reduces the number of solids being loaded as a pre-treatment before further filtration.

These rectangular channels or tanks divided into several sections are filled with gravel (sized between 4-30mm) to remove algae and turbidity. This allows the raw water to encounter the coarse and then more fine gravel as an inlet distribution chamber. The outlet chambers then gather the filtered water leaving behind any solids.

Slow sand filters can also remove microorganisms, algae and turbidity which is a suitable treatment for small supplies when there is a sufficient amount of land available. Unlike gravel filters, these are tanks which include a much smaller density of material with the sharp sand being between 0.15-0.30mm to a depth of 0.5-1.5mm.

This process sees the transfer of oxygen into water, followed by the removal of gases and volatile compounds through air stripping. Thanks to their energy efficiency and compact design, packed tower aerators are a common method used to achieve this.

Contaminants in water can be removed using activated carbon and physical adsorption. The nature and concentration of the contaminant, the amount and type of carbon, as well as the retention time of the water in the unit and the overall quality of the water will affect this step. Filters in replaceable cartridges will help to remove carbon fines from the end product.

Applied to the treatment of water, reverse osmosis, ultrafiltration, micro filtration and nanofiltration are commonly used membranes for the process. It adequately removes Giardia, Cryptosporidium, pathogenic bacteria and potentially bacteriophages and human viruses.

The ability to drink water straight from a tap is something that we take for granted but is a significant health and safety preoccupation for site facility managers, water hygiene technicians and employers. There are times when your drinking water would be compromised, especially if it is subject to contamination.

This is particularly true if it is being fed from alternative sources such as boreholes. However, the greatest risk to our health comes from viruses, infections and waterborne pathogens stemming from the building water distribution system it sits in.

Between water entering our buildings to when it comes out of the tap, there are interferences which could harm our water.

Portable water is another name for drinking water, water that is safe for us to consume but can also be used when washing utensils, dishes and for cooking.

As mentioned, there are external and internal factors which can affect our drinking water. Luckily there are a number of ways for us to efficiently and effectively manage this so that it doesn’t cause any harm.

Pathogenic microorganisms can enter the water distribution system and can lead to microbes such as E. coli. Given the right conditions for opportunistic pathogens, they can become highly tractive host environments in water distribution systems.

From Salmonella to Hepatitis A, Legionella Pneumophila and Cryptosporidium, these pathogens can cause infection, particularly amongst vulnerable people with impaired or weak immune systems, as well as children. Although many biofilms cause no real threat from water distribution systems, they can still block intake valves and corrode pipes after a while.

There are a number of water treatments that can help kill pathogens including chlorine, however, some disinfectants can further promote their growth. So it’s important to take the right steps and monitor the microbiology and bacteria in the water.

The conditions of the pipes in your domestic or commercial building can influence what chemicals can be released into the system and the types of bacteria that can grow within the system itself.

Older pipes are more prone to develop a large amount of scale and rust, whilst other pipe materials can break down iron, phosphate and hydrogen meaning that bacteria can multiply.

There are some efficient ways to maintain healthy pipes such as using water softeners to reduce scale, as well as water treatment chemicals to coat the inside of the water distribution pipes.

The physical being of the water system is sustained through pipes, and if there is a leak or a break in the works then this can lead to low-pressure movements which cause bacteria to hold onto surfaces.

This can also encourage biofilm growth and any sediments that get into the systems can cause bacteria to grow. Alterations to the pipework can impact the system as well, but once the pressure has been restored, bacteria growth can break off and this can put the water system at risk.

Water age and hydraulic pressure can be affected by the type of storage facility that it is held in. Water tanks, particularly ones that do not turn over frequently, can encourage microbiological activity and cause the disinfectant concentrations to drop, increasing the bacteria’s growth ability.

Temperature, stability and source can also impact the quality of consumable water in a number of different ways. If the water becomes stagnant over time, its disinfection concentration can decrease encouraging growth.

Whilst chemical stability means that once the water has been treated it can also enhance microbiological growth with changes in temperature and disinfectant dosing for example. This is why treatments can be altered in hotter countries and seasons.

Laboratory analysis services and water testing can assess what may be happening to the water’s chemistry. With effective testing, you’ll be able to make better decisions on how to treat the water for a healthier outcome.

When looking to improve the quality of your water, there are a number of water treatments to enforce depending on your water usage, flow rates, objective and application. More often than not, a combination of techniques may be required.

A low-cost and simple method, UV disinfection is a popular choice because it is an efficient and effective way to kill fungi, viruses, bacteria and cysts that may be found in water. Usually used alongside other methods it cannot solely remove heavy metals, particulates or gases, therefore bacteria can still be hidden behind large debris.

A successful way to remove manganese, iron and sulphur while destroying microbiology, bacteria and viruses, ozone is a fast method to decompose and cut down any harmful by-products, tastes and odours from disinfectants. It is produced when oxygen is exposed to high-voltage current and is particularly useful when using chlorine in the water system.

If you’re the owner or director of a company, you’ll be responsible by law for the building and water systems in which employees and users work in.

Their safety is a priority, and as a duty holder, a named person for the control of Legionella Bacteria will ensure compliance and keep individuals away from harm. It is a requirement under the Health & Safety Executives Approved Code of Practice ACOP L8 for a person to take responsibility for mitigating risk.

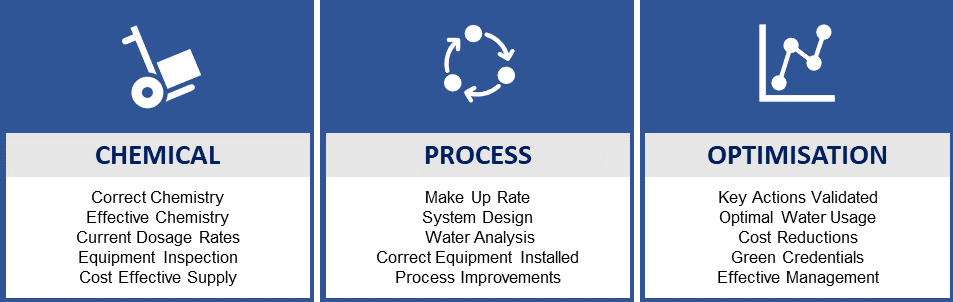

The cost of water and its treatment across a building can be extensive but at Primary Water Solutions, we can help ensure the water on site is optimised, at the correct quality for the process application and that the water required within a process is used efficiently as possible.

To make the extensive process even easier for you, we are now offering a professional water treatment survey free of charge where we will distinguish where we can help:

So if you are looking for any water treatment advice or alternative supplier options, please contact Primary Water Solutions today on 01454 501 8181 or visit our website for further information.